Concentrated defoamer

- Inquire

- Add To Basket

Concentrated defoamer

HR-8404J

Product Characteristics

Especially suitable for water-based coloring systems;

Excellent defoaming effect in the grinding process;

Highly efficient, low additives

make up

Polysiloxane-polyether copolymer;

Contains fumed silica.

Specification

Appearance: slightly turbid liquid

Active ingredient (%): 100

Density: 1.00-1.05g/mL

Viscosity (25℃): 500-1500 mPas

Scope of application

●Designed for use in a variety of base systems such as styrene/acrylic emulsions, pure propylene emulsions, PVAc and terpolymer emulsions;

●The defoamer properties vary with different systems and formulations. Kimber CD-65 defoamer is compatible with acrylic, epoxy, polyester and polyethylene systems.

Compatible with acrylic, epoxy, polyester and polyethylene systems. Thorough, reproducible testing is required prior to large-scale production to ensure that desired performance is achieved.

desired performance.

Usage

● Particularly suitable for defoaming in the color paste grinding process;

● Addition during the dilution process or in the varnish requires high shear conditions or pre-dilution;

Due to the presence of fumed silica, pre-dilution can lead to cloudy solutions and pre-dilution storage stability is reduced;

● The long-term effective performance of defoamers depends on the coating system and should be measured in various formulations (if possible tested at different temperatures).

Architectural coatings

Recommended additions are 0.1 to 0.5% of the total formulation.

Recommended additions are 0.05 to 0.5% of the total formulation.

Printing inks

Wood and furniture coatings

Industrial coatings

Recommended to add 0.1 to 0.5% of the total formula amount

Recommended addition: 0.1 to 0.5% of total formula amount

Recommended to add 0.1 to 0.5% of total formula amount

Solubility

Mixing ratio (weight)) 1:100 1:4

Water - -

Isopropanol + +

Glycol butyl ether + 0

piracetam + +

Proglyde DMM + +

petroleum solvent + 0

-= turbid/insoluble 0=milky light +=open (non-secretive)

Handling Precautions

This material does not contain the required information for safe use of the product. You should read the product instructions, product safety information, product container label safety, physical and health hazard information before use.

Read the product instructions, product safety data, and product container labeling for safety, physical and health hazards before using the product, or request a copy of the product safety instructions from your sales representative.

Packaging, storage and transportation

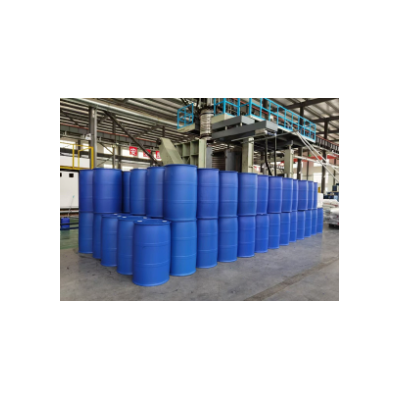

●The product is packed in 25kg, 200kg plastic drums, or according to customers' requirements.

Store at 2-40 ℃, in a cool, dry and frost-proof place, with a shelf life of 12 months from the date of shipment.

●This product uses water as diluent, non-volatile, non-toxic, non-corrosive, and is transported as general chemicals.

●Transportation Restrictions: Grade 1 frozen product, cannot be frozen.

Safety of use

●This product does not contain halogen, benzene, phenol, heavy metals and other harmful substances to the environment, in line with ROHS standards and SGS certification.

It has good characteristics of environmental protection, can be naturally degraded and does not pollute the environment.

●This product has not been tested or stated to be suitable for medical or pharmaceutical use.

Avoid contact with eyes and skin during operation. Before using this product, read the product manual and MSDS (Material Safety Data Sheet) carefully to understand the application.

Before using the product, you should read the product manual and MSDS (Material Safety Data Sheet) carefully to understand the scope of application, and do a small test experiment to ensure the safety of product use. If you have any questions, please call

For more information, please call us.